We recently had a MESA Pulse 360 bass amp in our new workshop for repair, with a fault description that it was powering up but not passing any signal.

I’d repaired an M-Pulse 360 last year with a identical fault condition, so we wondered whether the fault in both amps was being caused by the same component failure.

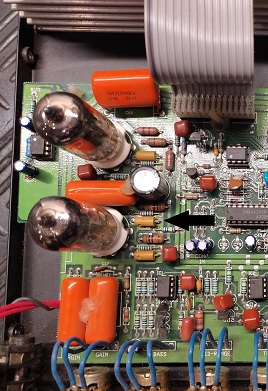

The M-Pulse 360 used tantalum capacitors in several positions in the pre-amp (see figure below). Whilst tantalum capacitiors are considered a “premium” part over standard aluminium electrolytics, they also have a reputation for unreliability. Rod Elliot of Elliot Sound Products has this to say about tantalum capacitors: “while many sing their praises, I do not recommend their use for anything, other than tossing in the (rubbish) bin.”

So why use tantalum capacitors? When compared to aluminimum electrolytics tantalum capacitors can be made smaller for the same capacitance, very useful if PCB space is tight, and have lower equivalent series resistance (ESR) which is useful for decoupling power rails in some applications. However, in this amp PCB space is not at a premium, nor is low ESR a major consideration, and if it was there is space to add a smaller value poly cap in parallel. Some people nay also use them because they are more expensive so must be better………

Anyhow, we openned the amp up and low and behold the same tantalaum cap was shorted as in the other M-Pulse I’d seen! To test the caps I simply unsolder one end and measured the resitance with the multimeter. The cap that has shorted was decoupling the +15 V rail supplying the op-amps in the pre-amp, dragging this rail to ground; without the +15V rail no signal was being passed. We replaced the cap with an aluminium electrolytic and the amp was back up and running.

Arrow showing aluminium cap relacing tantalum cap

And here is the amp being tested on the bench.