Here’s a repair I conducted on a more modern amp, a Aguilar AG500 bass guitar amplifier, where we were dealing with the dreaded SMDs.

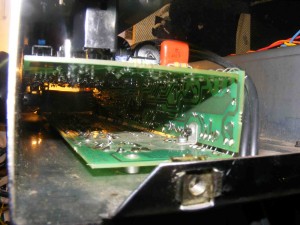

This amp is quite an interesting design as it has a class D output stage, however unlike most class D amps it’s not ultra light. It employs a linear power supply (rather than the SMPS that is de rigueur in class D amps), and so has a large, heavy mains transformer. It also doesn’t employ fan cooling, necessitating a relatively large heat sink.

Both these design decisions I think were made in the interests of reliability. Linear power supplies are generally more reliable than SMPS and can be easily repaired.

Relying on a fan for cooling means that the amp is imperiled by fan failure, a common problem in my experience.

Anyhow, the AG500 has 2 channels, and this one arrived in the workshop with one channel not working and the other have a very weak signal.

Injecting a signal into the power amp via the fx return showed that the power amp was working fine, so the problem was in the pre-amp.

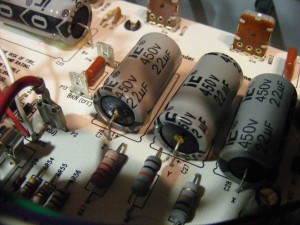

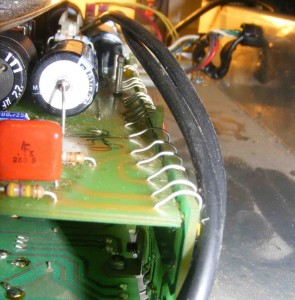

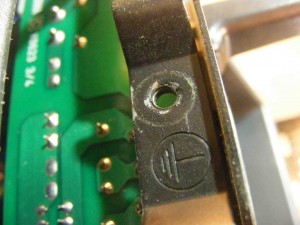

A quick look inside the amp revealed a PCB populated with surface mount devices (SMDs), and it was obvious that the pre-amp was a relatively complex design (for a bass amp!).

Fortunately Aguilar were very helpful (unlike many manufacturers…..) and, after signing the requiste NDA, supplied me with a service manual for the amp.

As the pre-amps channels are cascaded, failure in the first channel would significantly reduce the signal in through the other channel, so it was likely that the faults were caused by component failure in channel one.

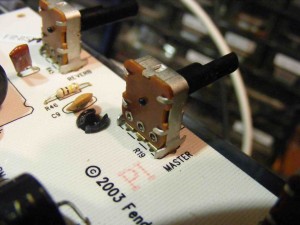

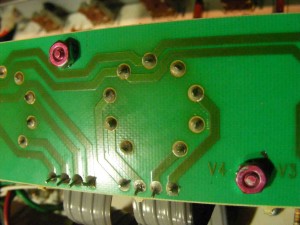

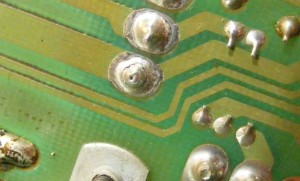

It soon became apparent that transistors Q1010 and Q1009 in the channelone had failed.

You can see where I’ve removed one of the offending items, with a biro in shot to give some idea of the scale of the problem. A steady hand is quite important in this type of repair.

Once these devices were replaced the amp worked fine; indeed it sounded very good.

Another snap of an SMD transistor & biro.